Sep. 02, 2022

A consumer asked what is the difference in the application of DTF ink and DTG pigment ink. For this trouble, let me evaluate it thoroughly. Before the analysis, let's talk about the current market's names for DTG pigment inks. A few of them refer to DTF textile ink, and some are called movie transfer inks. DTF textile printing inks and film transfer inks two names of ink are reasonably extensive. DTF textile ink will be a little bit extra straightforward, mostly emphasizing the application of DTF pigment ink.

Closer to the residence, in the two applications of DTF textile print and also direct to cotton print, both come from the application of pigment ink.

Via the above-described difference in the application process of both, in terms of hand feeling, the straight spray application of DTG pigment ink will most definitely carry out far better. Due to the fact that there is a layer of hot-melt powder in between the ink as well as the fabric in the DTF printing application, this is. The hot-melt powder is used as a binder and the ink is transferred to the fabric. The natural hand feel is reasonably worse than that of direct covering application. DTG pigment ink is directly published on the fabric, so there is normally no hand sensation issue. In regards to hand feeling, the application of a straight spray layer has noticeable advantages. On the other hand, as the application of DTF printing innovation matures and the application performance of warm thaw powder is boosted, the completed items made by DTF printing applications can also fulfill the requirements of market customers.

The biggest difference between the two applications is that the procedure is various. The DTF textile ink application is that the ink is printed on the warmth transfer movie, and after that, a layer of warm thaw powder is sprayed externally of the heat transfer movie, and after that, the shade is produced by pressing; while the DTG ink application is directly printed on the fabric. For far better shade and colorfastness, the fabric commonly requires to be used together with pre-and post-treatment liquids during the printing process. The process is relatively intricate for DTF print, as well as it often needs even more professional consumers to correct the alignment of the whole DTG print plan well. The DTF printing process is relatively easy, as well as the customer is very easy to quickly grasp the process, simple to promote and duplicate. This is likewise a crucial reason the DTF printing program is so popular.

The DTF printing application is even much better in regards to shade expression. Similarly, DTF printing carries out much better in regards to fastness. In order to boost the shade and fastness, straight spraying application usually needs the mix of pre-and post-treatment liquids to attain better outcomes, as well as the use of warm thaw powder in DTF printing applications flawlessly resolves the problems of shade as well as fastness. The hot-melt powder is made use of as a sticky to completely integrate pigment ink and material, as well as the shading efficiency and fastness performance after color growth is really exceptional. The issue of color and fastness is extremely bothersome in the application of DTG printing. The warm thaw powder is made use of as an intermediate tool to make the pigment ink and the material fit well, which completely resolves the old difficult problem of DTG printing application in regards to shade and also fastness.

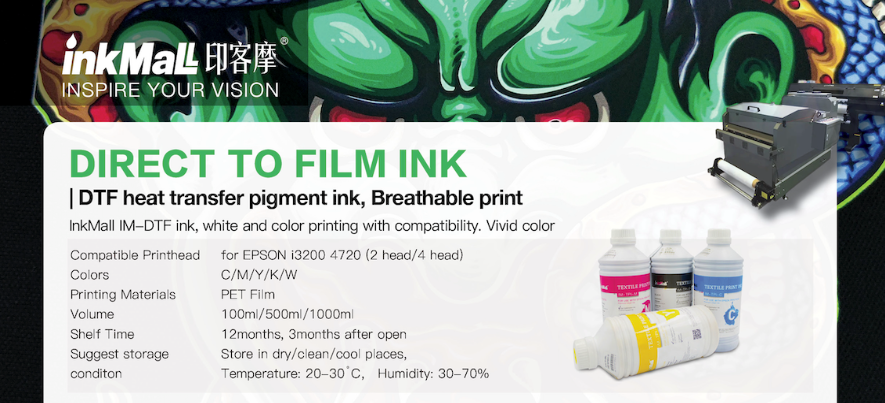

At present, the application devices for DTF printing are still mostly Epson 4720 nozzles, while the DTG printing is primarily commercial nozzles. The cost of the makers utilized in between the two is fairly different. In regards to ink costs, the DTF textile ink for the 4720 devices is additionally less expensive than the ink for DTG printing ink. The greatest price of the DTF printing application is the warmth transfer movie, as well as the rate of the warm transfer movie, is constantly falling. On the whole, the cost of DTF printing is less than the cost of DTG printing. DTF printing program has a reduced financial investment threshold, easy procedure, very easy access, as well as duplicating, so it creates swiftly and also is popular in a short time.

The above is what I showed my friends concerning the distinction between DTF textile printing ink and DTG pigment ink. Today, both services belong to pigment electronic applications. Both have their own benefits as well as negative aspects. The market positioning, as well as the client base, are still very large. Difference. DTF printing will definitely end up being the mainstream service in the individualized application, as well as the electronic printing of cotton towels will certainly be the main application of DTG direct to garment printing. Both solutions match each other and also will end up being the foundation of the rapid growth of the whole pigment digital printing.